The device invented by USF Health doctors, teaming with Tampa General Hospital, Northwell Health and Formlabs, has been used worldwide to address critical shortages of test kit swabs

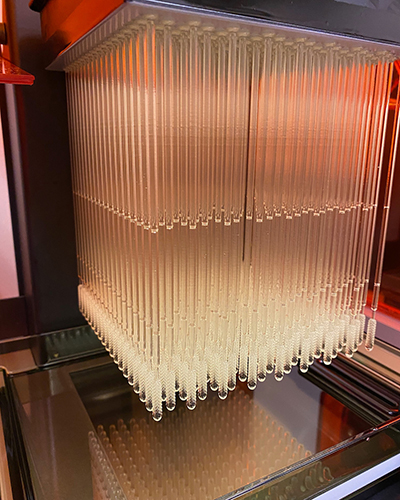

Tens of millions of the USF Health-invented 3D printed nasal swabs have been mass produced for use by health care providers worldwide. [Allison Long, USF Health Communications]

Now, a multisite clinical trial led by the University of South Florida Health (USF Health) Morsani College of Medicine provides the first evidence that 3D-printed alternative nasal swabs work as well, and safely, as the standard synthetic flocked nasal swabs.

The results were published online Sept. 10 in Clinical Infectious Diseases. A commentary accompanying the paper cites the authors’ timely, collaborative response to supply chain disruptions affecting testing capacity early in the pandemic.

Seeking a solution to an unprecedented demand for nasal swabs at their own institution and others, USF Health researchers in the Departments of Radiology and Infectious Diseases reached out to colleagues at Northwell Health, New York’s largest health care provider, and leading 3D-printer manufacturer Formlabs. Working around the clock, this multidisciplinary team rapidly designed, tested and produced a 3D printed nasal swab prototype as a replacement for commercially-made flocked nasal swabs. Bench testing (24-hour, 3-day, and leeching) using respiratory syncytial virus as a proxy for SARS-CoV-2, as well as local clinical validation of the final prototype (fabricated with FDA-approved nontoxic, surgical grade materials), was successfully completed in mid-March 2020.

The larger-scale clinical trial began in late March at three sites: Tampa General Hospital (TGH), Northwell Health, and Philadelphia-based Thomas Jefferson University Hospital. (Other sites joined later.)

The paper’s first author Summer Decker, PhD, directs the USF Health Radiology-TGH Division of 3D Clinical Applications, which creates and prints 3D anatomical models for surgeons and other clinicians and designs medical devices. [Allison Long, USF Health Communications]

“In the midst of a pandemic, our team of experts representing academic medicine, health care delivery systems, and the medical device industry put aside boundaries to quickly work together toward a common purpose,” Dr. Decker said. “It’s rewarding that the novel design for a 3D swab we created has been adopted around the world, equipping more providers to diagnose COVID-19 and hopefully help prevent its spread.”

The gold standard for diagnosing respiratory infections is to look for viral genetic material found in mucosal fluid collected with a long, slender swab inserted into the patient’s nose and back of the throat. The nasal swab is put into a plastic tube with chemicals that stabilize the sample until the virus-specific genetic material can be extracted and amplified by polymerase chain reaction (PCR) in a diagnostics laboratory. Conventional swabs feature a bushy tip coated with nylon flock; the USF Health doctors designed a tip with a 3D printed textured pattern able to capture a sufficient sample for COVID testing while keeping patient safety and comfort in mind.

Kami Kim, MD, infectious diseases division director at USF Health Morsani College of Medicine, led the multisite clinical trial comparing the performance of commercial nasal swabs with the 3D-printed alternative.

The clinical trial fully tested the safety and effectiveness of this 3D printed swab in 291 symptomatic adults undergoing COVID-19 screening at the TGH, Northwell Health and Thomas Jefferson University Hospital sites. The 3D printed nasal swab was compared to the standard synthetic nasal swab across three SARS-CoV-2 testing platforms FDA-authorized for emergency use — a modified version of the Center for Disease Control and Prevention’s real-time reverse transcriptase PCR diagnostic panel, and two commercial molecular diagnostic tests.

“This trial provided the first rigorous head-to-head comparison to make sure that the 3D swab performed as well as the standard,” said principal investigator Kami Kim, MD, professor and division director for infectious disease at the USF Health Morsani College of Medicine. “Across all three platforms used in our study, we demonstrated that the commercial swab and the 3D printed swab were comparable for accurate detection of COVID-19 infection.”

For both swabs, the only adverse patient reaction documented during the trial was a few instances of slight nasal bleeding. The cost of materials per 3D printed nasal swab ranges from 26-to 46-cents, while commercial swabs cost about $1 each, the authors reported.

Given the ongoing need for widespread COVID-19 testing, the study authors concluded that 3D printing technology offers a viable, cost-efficient option to address swab supply shortages, particularly when local hospitals or other clinical sites already have 3D printing labs equipped to print and process the devices.

The 3D printed nasal swabs were specifically designed for patients using FDA-approved surgical grade material. [Allison Long, USF Health Communications]

“Among all parts 3D printed during COVID-19, nasopharyngeal swabs have received the most attention, with participants ranging from humanitarians to charlatans,” Dr. Rybicki wrote in his summary. “The authors should be congratulated for staying on the right side of the curve, and for their perseverance, leadership, scientific rigor, and good will.”